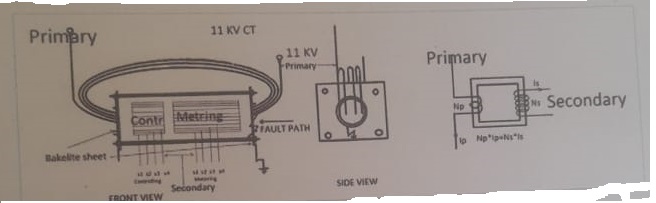

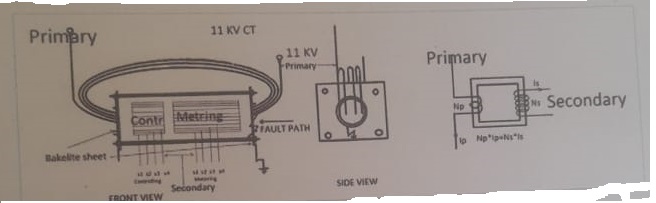

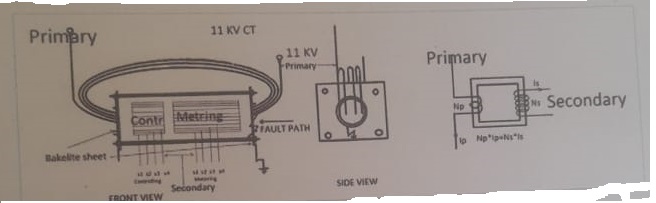

Smart Dc Supply in 33/11KV Power Substations

by Er Gheyasuddin MSc Engg(Power System)

Director(Operation)SBPDCL

Published in Urjasvani Nov 2014.

DC power supply in power substations are mainly used for operations of protective systems.For Dc Supply we use a bank of rechargeable

DC batteris of 30 volts.Historically these batteries were charged by diode valves which had limitatin of charging current.

They could not supply sufficient dc current to charge the batteries in short time. These chargers did not have the capacity to

to take the load of protective relays and tripping system on their own due to restricted capacity of thermionic emmission of diode valves and higher output resitance.

Obviously protection was dependent on two processes.Firstly the battery was charged which took a long time and thenafter only it could be used for protection ie tripping.If for any reason

the battery was not charged there was strong probablity of failure of protection during this charging period.In PESU six power transformers had burnt at once all at a time when power

transformers were charged after a power failure of 24 hours.The batteries had discharged during that period ,consequently the protection failed and 6 number of power transformers burnt.

During my inspection of power substations I observed that even entering in the age of solidstate PSS with a dc load of 12 amperes were being supplied by a charger of 5 amperes .

This was technically a very awkward situation.

This is also seen that when a new battery is brought in a substation it is charged in the market on 10 ampere.Then discharged and again recharged before putting it into service.This means conventional chargers could only maintain a charged battery when every thing was OK.

In present days in PSS dc indicator bulbs are abundantly used in control panels that cause the battery discharge quickly in short time rendering the protection ineffective and liable to fail. The relays of VCB mostly go defective due to their operation on low dc supply voltage.

Assured dc supply of proper voltage and minimum internal resistance readily available in pss means guaranteed protection of power substation equipments,transmission lines,animal livesand properties.A dc supply system plays the same role

in a pss that does a heart in a living animal.

It is a universal fact that batteries are subject to aging and after certain periods (3 to 4 years)they are not useable.

it is also seen that the dc load requrement for different substations are different for different substations.

Under above circumstances and in face of growing capacity and complexity of power system equipments it was a challenging need to develop such a dc supply system which could be capable of charging

the battery and at the same time be able to supply instaneous dc power to protective relays and trip coils.That could be possible only when AC converted to DC was also available to was supplied also to control system of PSS .

In order to overcome these situations it was a need to design such a charger which could cope with these situations.With a view to meet all the abnormal circumtances, the charger has been designed manufactured

and put in operation .In State of Bihar now all the 33/11KV PSS are using this charger for about 10 years. Previously the chargers purchased did not work for more than 6 months but with the use of this charger the failure rate has come to negligibly zero.

In this charger the components and elements have been so designed that they are able to withstand all possible abnormal situations like storm,line to line faults etc.This charger has been so designed and tested for short circuit currents .

In this charger no external resistance has been used which makes it capable of tripping the triping coil without dc battery.Dc batteries come into action when power is not available

in the substations for making or breaking the VCB connections.

I have found many sustations ,with this charger providing full protection without batteries.

The fabrication of online smart dc charger was most simple as detailed below.

The primary of 220/30 volt transformer is enamelled aluminium of 18 swg.

The secondary of transformer is alluminium 2.65 mmdiameter dpc(double paper coated varnished).

The iron core is of &number size.

rotary switch of 1 pole 8 throws 15 amperesfor chargin current adjustment.

Voltmeter 300 AC.

15 volts DC Ampere meter.

20 numbers of 10 Amp 220volt semi conducter diodes.for fullwave bridge rectifier.

10,000 Micro Farad 100 volts DC 2 numbers condenser for CLC pi filter.

An iron core inductor made of 3 number core and 13 swg enamelled copper winding.

The inductance of the inductor is about 9.8 ohms for 50 cycle frequency.

The smart online dc charger cum dc supplier is being manufactured at MRT Work Shop in Patna Electric Supply Circle

and its salient features are given below..

The AC components Of rectified Voltage (harmonics) are suppressed by CLC circuit.The ripple factor which is the ratio of rms values of harmonic current to the pure dc current is less than 1 percent. As no resistance is used in the circuit it is capable of operating the trip coil of vcb with 30 volts full voltage directly without any voltage drop in ndc supply circuit . In other words DC is being derived from infinite bus bar .Protection is required only when

power is present.If power is present it operates the relay and the vaccum circuit breaker even without a battery. Even in case of a weak battery,Protection is assured. This charger when used with battery is a complete solution

to DC supply. It is intanteneous in its action hence it does not matter how long the power has been off in pss and how long the PSS battery has not been charged.There is nothing like charging and tricle mode. Charging and tricle are achieved

automatically as per need.

A single unit unit of this system is capable to take the load of any capacity of PSS with a single battery set opposed to the conventional battery charger that are used in multipple numbers in large PSS .

It is highly sensitive and offers zero tollerance in respect of relay operation and tripping of trip coils of VCB.

It is generally observed in the PSS that when there is a short circuit in DC circuit of PSS there is heavy burden on on the DC battery and the

conventional charger does not meet the demand of extra short circuit current subsequently the substation's battery voltage goes down. and in case of fault

condition in transnsmission lines relay and protections do not respond.But in case of this smart and online System Dc current goes up in DC circuit fault condition. It maintains the battery voltage even even in this faulty condition

and gives required DC voltageto other healthy VCB Assuring the protection. The abnormally increased DC current is indication of some short circuit in DC circuit

and remedial action may be taken to rectify the fault .In other words it also acts as a DC circuit fault indicator .

These are exclusive advantages not found in other systems prevalent these days.By inclusion of this system the reliablity of protection has improved many times.

The system is so simple in its princple and fabrication that it can be fabricated and maintained by semi skilled persons. No heating elemnts have been used and the desgn has been done for minimum heat loss.Further complex electronic circuits with integrated circuits

used in chargers for regulation op power supply give less and take more at the cost of reliablity and durablity.All the components prone to ffrequent failure

have been remove and the smart charger has been made fully functional to deal with worst condition and almost maintenance free.

It is portable and is carried by one person.There is no problem of transportation.The size of core ,winding conductors,number of turns,number and capacity of diodes have been so chosen that heat generated in the system is negligible.and the life of the charger is long.

The cost of conventiona baterry charger is about 50 thousands where as the cost of Smart online charger is about Rs 10 thousands .

In 10 years the failure rate has been found 0.5 percent.